After trying the fabric arm for a few minutes I felt lightheaded. Unfortunately the fabric arm needs to be very tight in order to be rigid enough to work. Being able to breath is more important than moving, therefore this option is not an option. My original plan, before plan fabric, was to use a “Steadicam” type device to balance my arm. Normally used to keep a camera perfectly balanced against gravity, it is also the mechanism used in many tool holding devices, lamps, microphone arms, and many existing mobile arm supports. Unable to afford one of these devices, I 3d printed my own. It may yet work but it has a few problems.

One, it only works when perfectly perpendicular to the ground. This will cause problems when I need to tilt my chair or drive on New England pavement. This could be fixed by attaching the whole assembly on a pivot that maintains its position with respect too gravity. This would not work when the chair is tilted in the Y plane, and adds bulk which leads to problem number two.

Two, this mechanism is very bulky. It adds a foot and a half of width to both sides of my chair. My chair is already 30 inches wide and barely fits through doors. Taking the devices off every time I encounter a door would negate any independence these devices give me.

Three, it may be too late. A passive exoskeleton still requires some strength to use, strength I had that is now gone. An active device is another story.

The easy part of an arm exoskeleton is the elbow, its only one degree of freedom and sensing my muscle movement should be easy. There are medical devices that do this already, however they are useless to me without the shoulder. Fortunately shoulder support exoskeletons are popping up everywhere. Intended for the factory environment to reduce workplace injuries from repetitive above head motions, they could be repurposed for my use instead. Not so fortunately, these products cannot be used while sitting down in a chair. These devices could be modified and placed on the back of my wheelchair however. The most compact design I have found so far is the Ottobock Paexo, and a close second is the ShoulderX from SuitX.

The ShoulderX could probably be attached to my wheelchair without any modification, however this design is not very flexible and must be placed in a particular way. This is disappointing as this design could easily be motorized without adding much bulk.

The Paexo design has given me an idea.

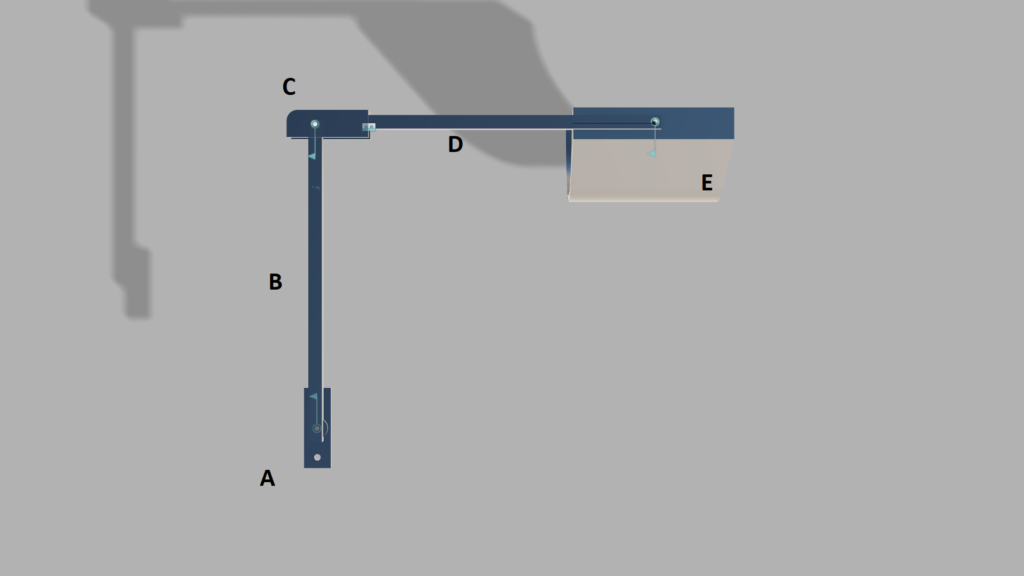

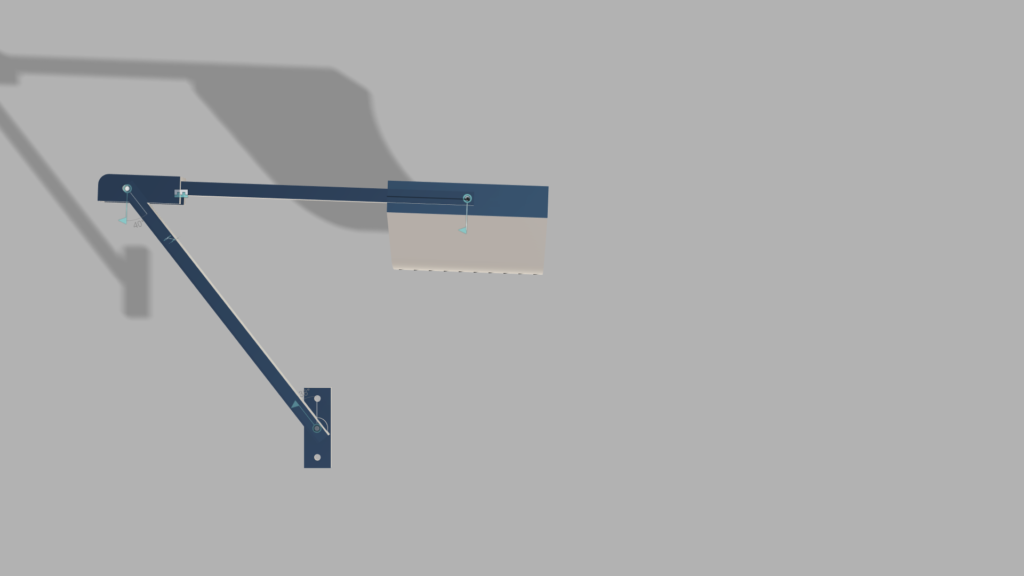

Here is a quick sketch of my next idea:

I’m nowhere near done but the basic idea is here. Here is a quick rundown:

- E This is the brace that will be strapped to my arm, allowing the rest of the device to move my arm around.

- D Just the rod connecting E to C, it has no joints except for a ball joint attaching to E

- C This is a revolute joint between D and E

- B The rod connecting C to A, not shown is B can twist, allowing side to side movement of E

- A The attachment bracket for my wheelchair’s side rail. Also contains a revolute joints for B

This device will need to be motorized on every joint and that presents my largest hurdle. This device i’m now calling Plan C, is really a robot arm in disguise that uses my arm as it’s payload. I need to learn too many things before I can tackle this, advanced topics that need years of study to understand. I’m leaving the realm of screwing around and into Engineering. I can’t afford to hire an Engineer, so my only option is to become an Engineer myself. So I enrolled in college for Electrical Engineering and will start soon.